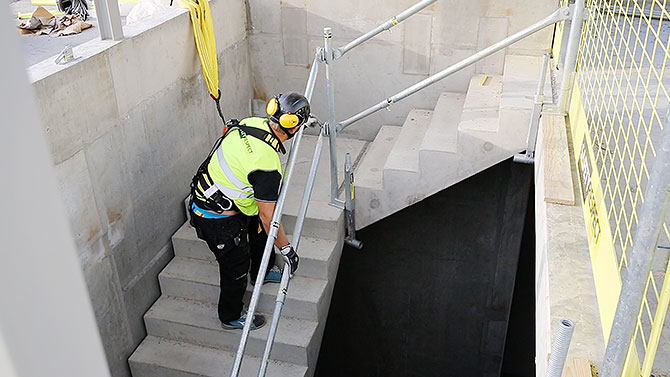

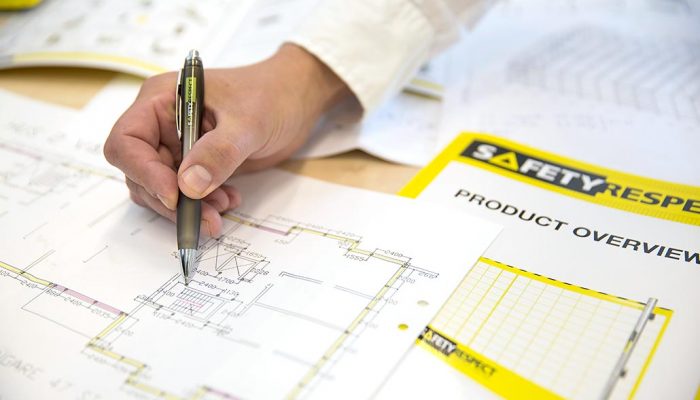

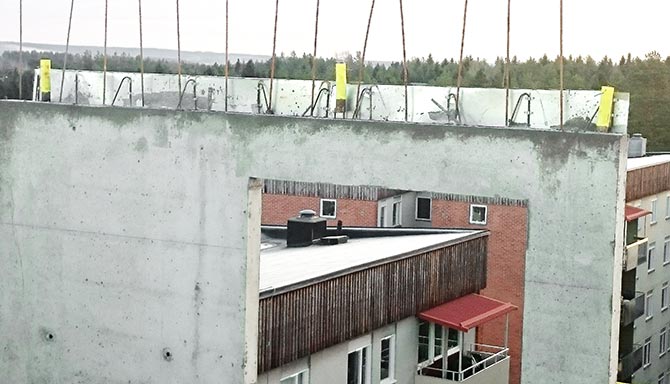

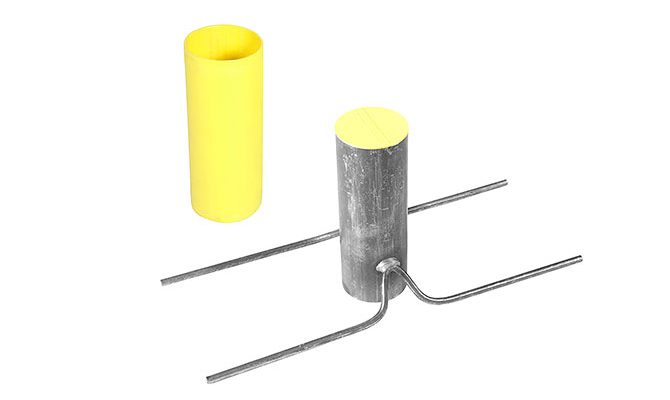

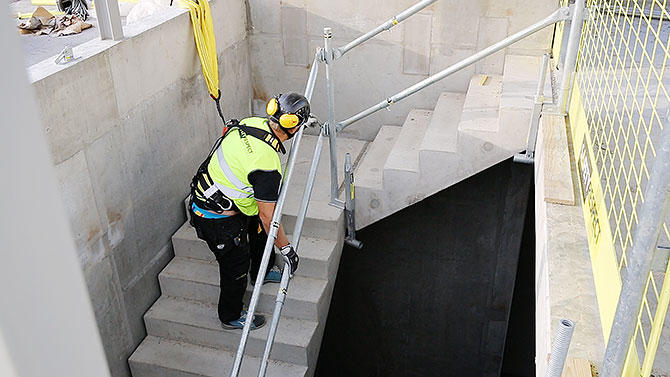

We can service an already installed edge protection based on a SafetyCheck that has been carried out at an earlier stage. We make the necessary corrections of possible defects, make additions to the edge protections, optimise material of delivered and installed edge protection, move and remove materials on slabs, etc. We look forward and solve future edge protection situations.